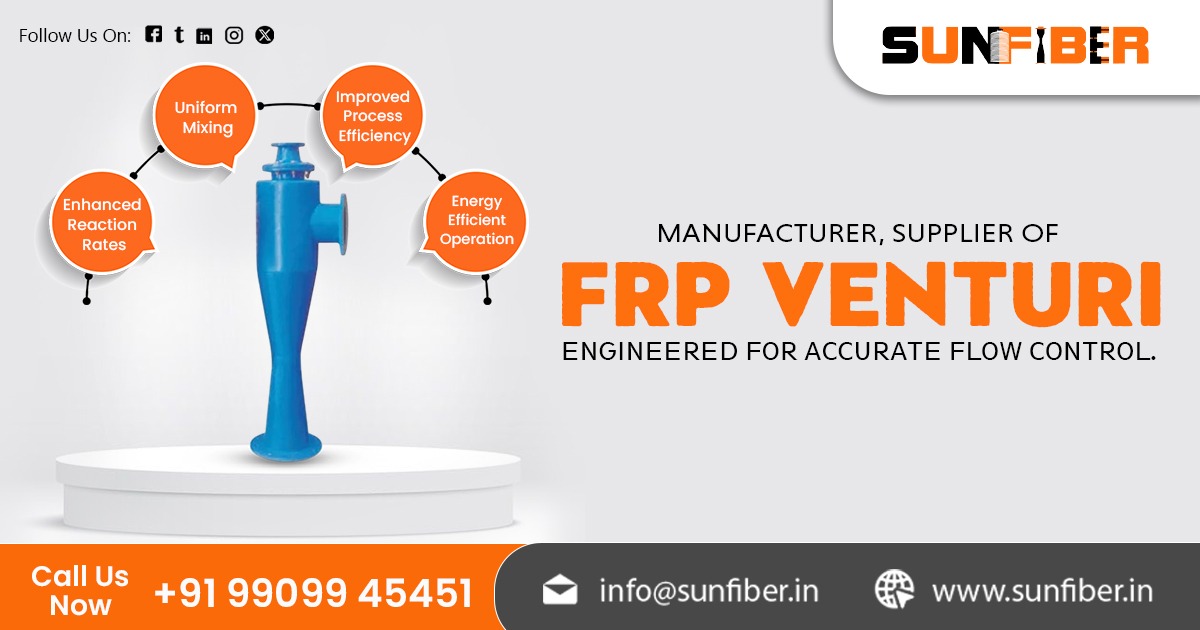

Sunfiber is a prominent Manufacturer and Supplier of FRP Venturi in India.

Our manufacturing unit is in Ahmedabad, Gujarat, India.

A FRP Venturi is a highly efficient air pollution control device designed to remove dust, fumes, and particulate matter from industrial exhaust gases.

The FRP Venturi operates on the Venturi principle, where gas velocity increases through a narrow throat, creating strong turbulence for effective pollutant capture.

Their lightweight yet robust construction makes them ideal for harsh industrial environments where metal systems may corrode quickly.

It provides a cost-effective, energy-efficient solution for industrial air pollution control, ensuring reliable performance and reduced operational costs.

We manufacture FRP Venturi units using fiber reinforced plastic, ensuring excellent resistance to corrosion, chemicals, and moisture.

Why Choose FRP Venturi from Sunfiber?

Proven expertise in FRP pollution control equipment

Superior corrosion and chemical resistance

Custom-designed systems for specific industrial needs

Long operational life with minimal maintenance

Cost-effective alternative to metal venturi scrubbers

Easy installation and handling

Optimized for high flow efficiency

Features of FRP Venturi for Sunfiber:

Corrosion & Chemical Resistant: Premium FRP withstands acids, alkalis, and chemicals.

High Strength & Durable: Reinforced structure for high pressure and flow.

Lightweight & Easy to Install: Simplifies transport, installation, and maintenance.

High Flow Efficiency: Optimized venturi throat ensures effective gas acceleration.

Smooth Inner Surface: Reduces friction and prevents material buildup.

Weather & UV Resistant: Performs reliably outdoors under harsh conditions.

Low Maintenance & Long Life: Minimal wear reduces operational costs over years.

Thermal Stability: Maintains performance under varying temperatures.

Eco-Friendly: FRP is recyclable, supporting sustainable operations.

Applications of FRP Venturi:

Sunfiber’s FRP Venturi systems are widely used in:

Chemical processing plants

Pharmaceutical industries

Fertilizer and pesticide manufacturing

Power plants and boiler exhaust systems

Metal processing and foundries

Cement and mineral processing plants

Pulp and paper industries

Acid handling and corrosive gas applications

FAQs – FRP Venturi

Q1. Is it corrosion resistant?

Yes, FRP Venturis resist acids, alkalis, chemicals, and moisture, making them ideal for harsh and corrosive industrial environments.

Q2. How lightweight is it compared to metal alternatives?

FRP Venturis are significantly lighter than metal venturis, enabling easier handling, transportation, installation, and maintenance.

Q3. How efficient is the flow design?

Optimized venturi throat and smooth inner surfaces ensure minimal friction losses, high suction efficiency, and stable fluid or gas acceleration.

Q4. Can it handle abrasive fluids?

Yes, reinforced FRP construction provides resistance against mild abrasives, preventing erosion and material degradation.

Sunfiber is a Manufacturer and Supplier of FRP Venturi in India Including Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal.

Contact Details:

Phone: +91 99099 45451

Email: info@sunfiber.in

Feel free to contact us for more information and inquiries.

View Product: Click Here